How Moisture-Proof Feed Trucks Protect Nutritional Value

The Hidden Cost of Moisture Ingress

Moisture is the silent enemy of feed quality. Its impact is multifaceted and costly:

Nutrient Degradation: Vitamins and certain additives are highly susceptible to moisture, which accelerates their oxidation and breakdown. This means birds receive a less potent feed, directly impacting growth rates, feed conversion ratios (FCR), and overall health.

Mold and Mycotoxin Growth: Moisture creates the perfect environment for mold proliferation. Certain molds produce mycotoxins, which are harmful compounds that can suppress immune systems, cause organ damage, and lead to significant production losses. The cost of a mycotoxin outbreak can be devastating.

Caking and Bridging: Moisture causes feed particles to clump together. This leads to caking inside the truck's compartments and, even worse, "bridging" in the farm's bulk bins—where feed refuses to flow out, halting Automated Feeding systems. This requires manual intervention, creates delays, and results in feed waste.

Reduced Palatability: Damp, musty feed is less appealing to poultry. Reduced intake directly translates to slower weight gain and uneven flock development.

tandard trailers are not designed to combat this. Seams, imperfect hatches, and condensation offer ample opportunity for humid air and external moisture to invade.

Engineering a Barrier Against the Elements

Moisture-proof feed trucks are engineered with a multi-layered defense system to create a sealed, stable environment for your feed.

Hermetic Sealing: The foundation of moisture protection is superior sealing. High-quality trucks feature continuous welds and use advanced food-grade sealants on every seam and panel joint. Heavy-duty, gasketed hatches are engineered to form an impervious barrier, locking out rain, humidity, and even fine dust during transit.

Condensation Control: A major source of moisture comes from within. This occurs through condensation when warm, moist air inside the trailer cools overnight. Advanced trucks combat this with insulated panels. Much like a thermos, this layer of insulation regulates the internal temperature, preventing the drastic temperature shifts that cause water to form on the interior walls and ceiling. This is a critical feature for operations in regions with significant day-night temperature fluctuations.

Food-Grade Internal Coatings: The interior surfaces are treated with smooth, non-porous, and anti-static coatings. This serves two purposes: it prevents moisture from clinging to the walls, and it facilitates a complete, clean discharge of feed, leaving no damp residue behind that could spoil the next load.

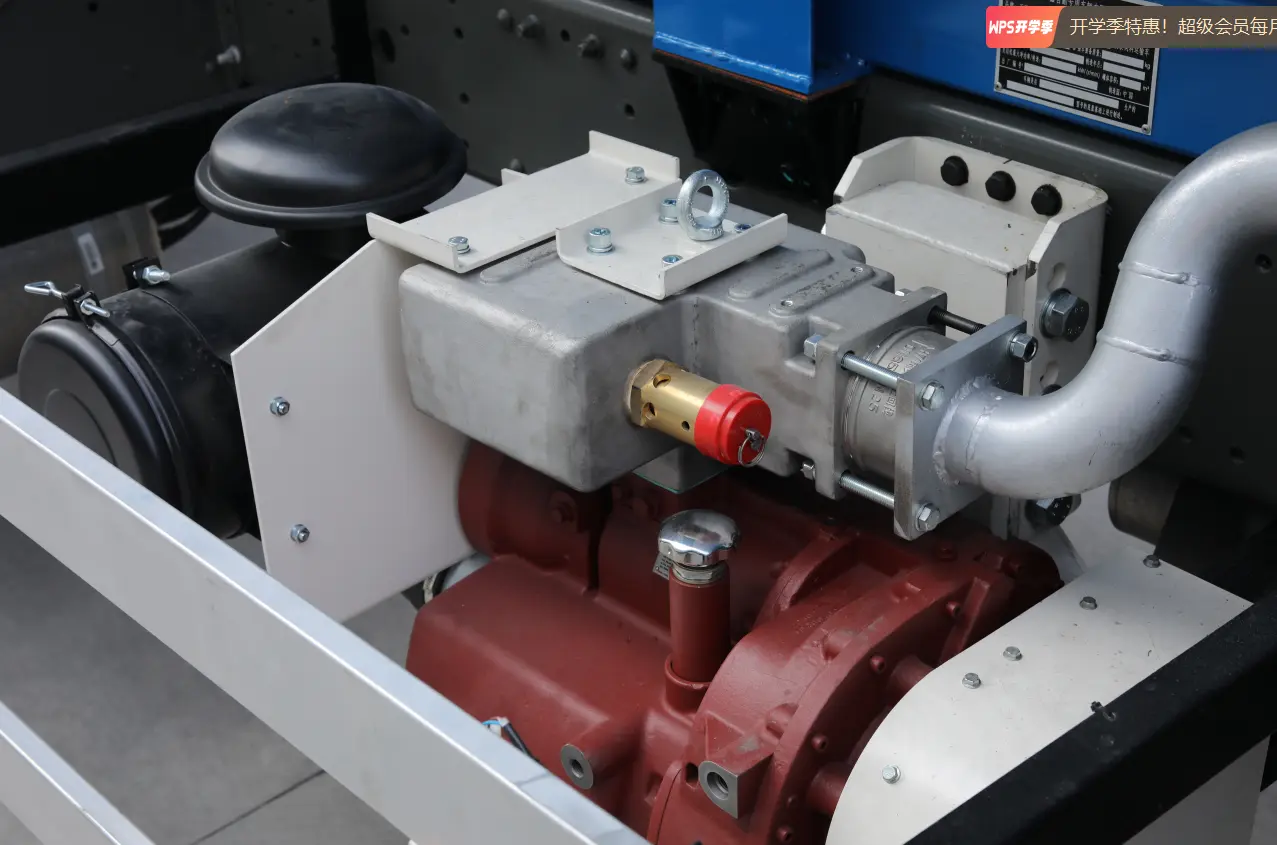

Pressurized Air Systems (Optional on some models): Some state-of-the-art vehicles incorporate a positive air pressure system. By pumping a slight amount of filtered, dry air into the compartments, they actively prevent moist external air from entering through any microscopic openings.

The Direct Link to Profitability: Protecting Your Investment

Investing in a moisture-proof truck is an investment in nutritional integrity. The benefits directly impact your bottom line:

Consistent Nutrient Delivery: By ensuring the feed delivered to the birds is identical to the formula created by your nutritionists, you guarantee optimal growth and performance. You pay for nutrients; moisture-proofing ensures your birds consume them.

Elimination of Mold-Related Losses: The virtual elimination of moisture drastically reduces the risk of mold and mycotoxin contamination. This means healthier flocks, reduced veterinary costs, and avoidance of catastrophic production drops.

Zero Waste, Maximum Flow: With no caking or bridging, every kilogram of feed is discharged efficiently from the truck into the bin. This eliminates waste, reduces labor for bin clearing, and ensures a smooth, uninterrupted feeding schedule.

Enhanced Feed Mill Flexibility: With a trusted moisture-proof transport system, feed can be loaded and shipped with confidence, even if ambient humidity is high or short-term storage is required, providing greater operational flexibility.

In conclusion, the value of feed is defined by its nutritional content. Allowing that value to degrade during the final leg of its journey is an avoidable financial drain. A moisture-proof feed truck is not merely a transporter; it is a mobile preservation unit. It is a strategic decision that safeguards the quality of your single largest input, protects the health of your flock, and ensures the hard-won gains of your nutrition program are delivered intact, bite by bite.