Poultry farming can be rewarding, but it requires the right tools. Chicken equipment plays a crucial role in ensuring optimal health and productivity. Farmers need essential tools to navigate daily challenges.

A well-equipped farm leads to better care for chickens. From feeding systems to disease control, each piece of equipment has its own importance. Investing in quality chicken equipment can save time and improve efficiency. However, not every tool may suit every farm.

Choosing the right equipment requires careful thought. Some farmers may overlook the importance of proper equipment. A mistake in selection can lead to stress for both birds and farmers. Therefore, understanding your needs is essential for success in poultry farming.

Choosing the right housing for your chickens is critical. The quality of coops can impact chicken health and productivity. According to industry reports, well-designed coops can reduce mortality rates by up to 10%. Proper ventilation and space can lead to happier, healthier birds.

When selecting a coop, consider the size and materials. Chickens need about 4 square feet each inside a coop. Outside, they require space to roam. Overcrowding leads to stress and disease. Additionally, coops should have sturdy perches, nesting boxes, and adequate protection against predators. Around 70% of poultry farmers reported issues with predation in poorly secured coops.

Don’t overlook maintenance either. A clean environment prevents disease outbreaks. Employing materials that are easy to clean will save time. Yet, many farmers neglect this aspect, leading to costly health problems. Evaluating your coop regularly is essential for long-term success. A little reflection on housing can lead to big improvements.

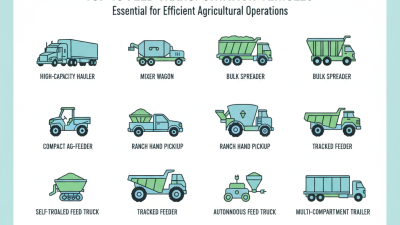

Feeding equipment is essential for every poultry farm. These tools help ensure birds receive a balanced diet. Proper nutrition impacts growth rates and egg production. Let's explore some key pieces of feeding equipment that can make a difference.

Automatic feeders can save time and labor. They distribute feed evenly, preventing waste. However, they require regular cleaning to avoid mold and spoilage. Manual feeders are also useful, especially for small farms. They allow close monitoring of feed intake but can be labor-intensive. Balancing equipment is crucial; overfeeding can lead to health issues.

Waterers are just as important as feeders. Chickens need access to clean water at all times. Poor hydration affects overall health and productivity. Some farmers overlook this aspect, leading to problems. Regular checks for leaks or clogs are necessary. Maintaining these feeding tools is key to a successful poultry operation. It requires diligence and reflection on best practices.

| Equipment | Purpose | Key Features |

|---|---|---|

| Automatic Feeders | Ensure a steady supply of food | Time-saving, adjustable feeding rates |

| Watering Systems | Provide constant access to fresh water | Durable, low maintenance, automatic refill |

| Nutritional Supplements | Enhance feed quality | Vitamins, minerals, and probiotics |

| Bowl Feeders | Facilitate easy feeding | Variety of sizes, easy to clean |

| Feed Storage Bins | Store feed securely | Weather-resistant, rodent-proof |

| Egg Incubators | Hatch eggs efficiently | Temperature control, humidity settings |

| Brooders | Warmth for young chicks | Heat source, adjustable height |

| Ventilation Systems | Maintain air quality | Fans, ducting, temperature control |

| Manure Management Tools | Efficient waste disposal | Spreaders, composters |

Watering systems are crucial for keeping poultry healthy. Proper hydration directly impacts growth and egg production. Chickens need clean water every day. Without it, they may suffer from dehydration or health issues. A reliable watering system ensures that fresh water is always available for your flock.

Using nipple drinkers can help minimize water wastage. These systems offer a steady supply without spilling. However, they require regular maintenance. If not cleaned, bacteria can build up quickly. It's essential to check the water quality often. Over time, you may need to replace some components to maintain efficiency.

Consider the layout of your farm when installing hydration systems. Accessibility is key. Birds should be able to reach water easily. Additionally, observe their drinking habits. Some might drink excessively while others do not. This can indicate health issues. Reflecting on these details can enhance your poultry farming practices significantly.

Effective health monitoring gear is crucial for poultry farms. Chickens are susceptible to various diseases. The World Organization for Animal Health reported that poultry diseases cost farmers billions annually. Investing in monitoring equipment can prevent these losses.

Temperature and humidity sensors are essential. Chickens thrive in specific conditions. If temperatures fluctuate, it can lead to stress or illness. Regular monitoring ensures these conditions remain stable. Keeping records of fluctuating temperatures can reveal hidden issues.

Blood testing kits provide insights into flock health. They allow farmers to detect diseases early. Early detection is key to preventing outbreaks. Many farmers overlook testing frequency. Not testing consistently can expose flocks to significant risks. Consideration of these tools ensures healthier birds and improved productivity.

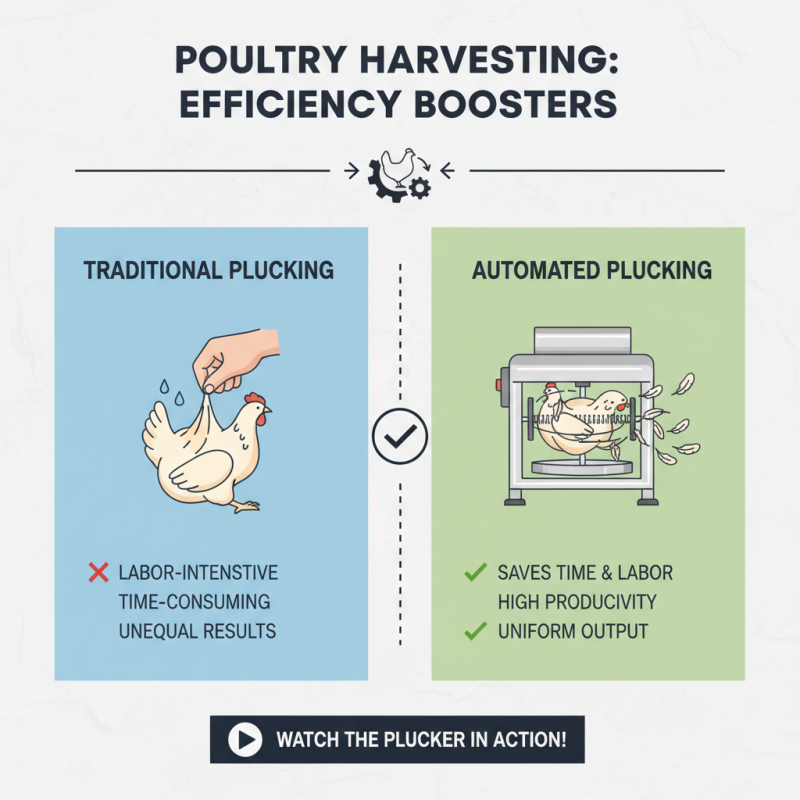

Harvesting and processing chicken efficiently is vital for any poultry farm. Proper tools can make a significant difference. Firstly, consider using specialized pluckers. These machines save time and labor. They remove feathers quickly, offering better productivity. Manual plucking is labor-intensive and can lead to uneven results.

Another tool worth having is an automatic gutting machine. This device streamlines the processing of birds, reducing the risk of contamination. It helps ensure that each chicken is processed quickly and hygienically. However, these machines can be costly. Farms must weigh the investment against potential savings in labor and time.

A meat saw is essential for further processing. It allows for cuts of various sizes. Not having one might lead to inconsistent portions. A quick note, improper handling can also lead to safety hazards. Training staff thoroughly is critical. Remember, efficient processing not only boosts output but also emphasizes quality.